Who would have thought that water would be an issue in Antarctica? The ice sheet we live on down here holds 90% of the worlds surface fresh water supply but its all contained in one big frozen lump. Its probably fortunate that it is all frozen because if it were to melt it would raise the sea level by over 60 metres which would flood all our state capitals and only leave Canberra. And no one wants that.

All three Australian Antarctic Research Stations have water access problems but Davis Station where I am working this year has the biggest problem. Located in what are known as the Vestfold Hills, we are many kilometres away from the ice shelf and to access water we have a reverse osmosis or desalination plant. I’m not really sure of the correct term. We just call it the R.O and as plumbers it happens to be one of our main jobs for the year. In a nutshell or actually a small green building, we turn sea water into drinking water and then store it in large tanks to provide the year-round water supply for the station. A few years ago we would then turn the water into beer but we’re not allowed to do that anymore.

The building is located about half a kilometre from the ocean on the shore of a small lake which we call the tarn. Every five years we set up a really big pump near the ocean and pump millions of litres of seawater into the tarn and that becomes the water supply for the RO. Unfortunately for 9 months of the year both the ocean and tarn are frozen solid, so we have to make the whole years supply in the three months over summer. In reality, we only get about 6 weeks of water production time. When its up and running we can produce about 70,000 litres every 24 hours which we pump to our two external, insulated, 600,000 litre storage tanks. Water usage for the 24 people we have on station over winter is about 3000 litres per day and can be as high as 10,000 litres over the summer when the station is full with the seasonal summer crew. When the ship arrives with the summerers, it usually also brings 200,000 litres of fresh water with it which we have to manually truck across the sea ice in two 8000 litre water trucks and put into our storage tanks.

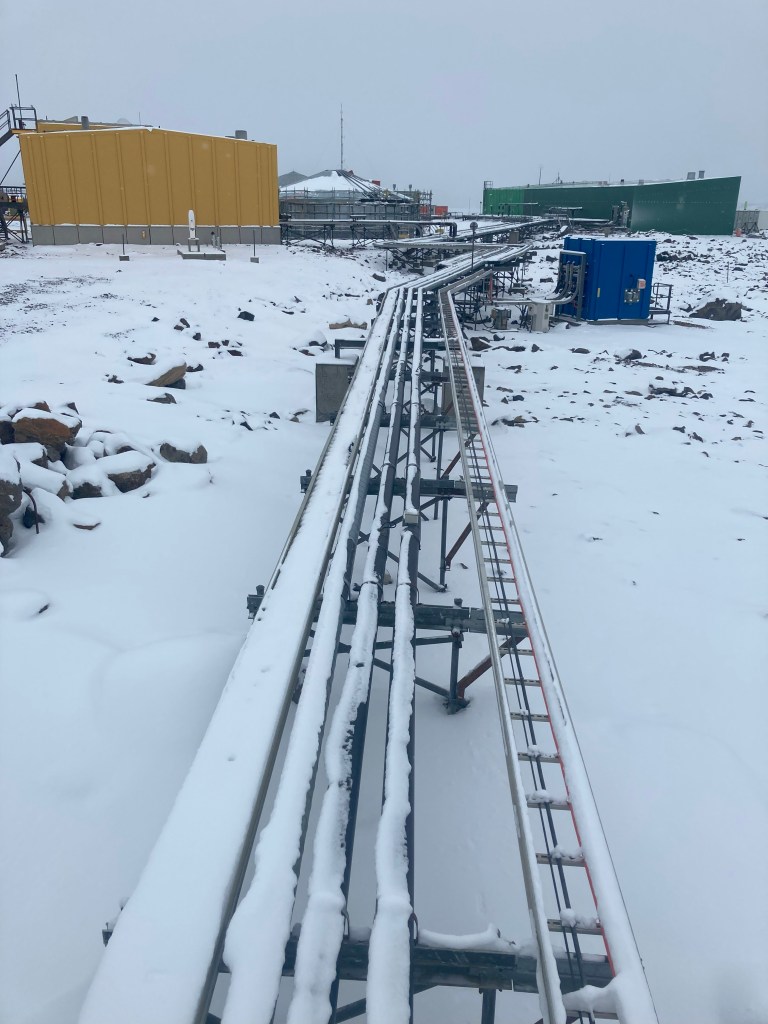

As soon as the icy surface of the tarn melts, we use a crane to lift in an aluminium floating pontoon which allows us to get to the deepest part of the lake. We then install a pump which is fixed to a winch and connected to insulated and heated pipework that runs up to the RO building. There are so many variables such as weather and water temperature that dictate when we can start or when we have to finish production. Although the plant is in sleep mode over the long winter we have to flush the system every two weeks while it is not being used. The plant is quite old now and once we start it up, it takes a lot of fine tuning, part replacement and plumber anxiety before we get the first litre of water.

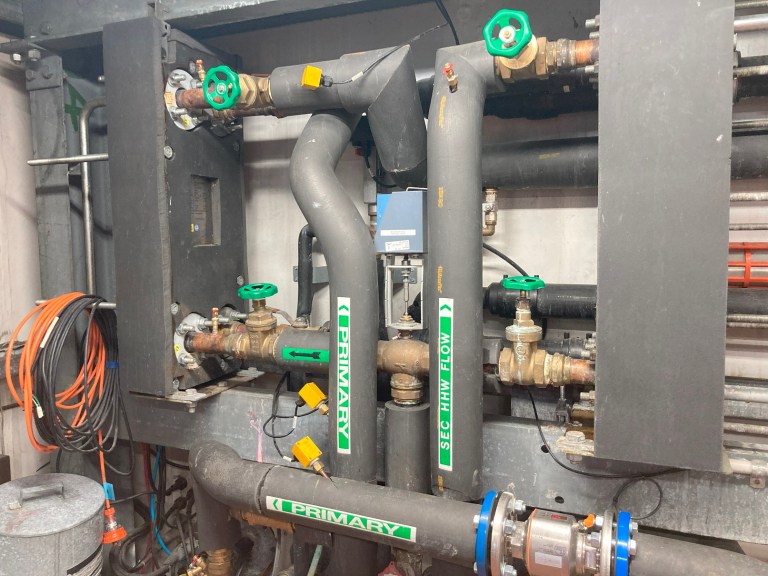

This year the incoming water to the plant never got higher than about 4°C and got as low as -1°C but our aging plant likes the water to be 20°C so we have to preheat it. We do this with two heat exchangers that use a combination of excess heat from our main powerhouse generators and a diesel fired boiler. A reverse osmosis plant is just like a fancy household water filter on steroids Basically, the water gets heated up, pumped through a sediment filter, then a bigger pump forces the water through ultra fine filter tubes and then an even bigger and more powerful pump forces that water through even stronger membrane tubes, that take out all the salt particles and bacteria and send clean clear fresh water through to a smaller tank where we then pump it off in batches to the big storage tanks. It has lots of other power saving gadgets and gauges and valves to make it more complicated and keep us employed. The excess and salty water from the process gets returned through a heated insulated pipe back into another part of the tarn. As the cold weather sets in so do the faults created by the ingress of snow into the heated pipework and the fear of ice chunks being sucked into the pump or the force of the freezing water in the tarn crushing the tanks on the pontoon. And it’s cold. We watch the weather carefully as we have to allow for a good weather day to set up the crane again and reverse the set-up process. And then as quick as it started it’s all over.

There is a third tank under construction and a new RO plant ready to install next year. In Antarctica you get to do that outside construction work over summer when you have long days and reasonable weather.

This year we produced about 1.5 million litres of water which should easily get us through the winter and allow the summer crew to have enough water until late January when the tarn melts and the tanks can be refilled. Everything is good. Except for when you discover one of your big tanks has sprung a leak!

Wow, that’s amazing. Hope you are well? I’m enjoying your stories.

LikeLike